What is FR4 Material?

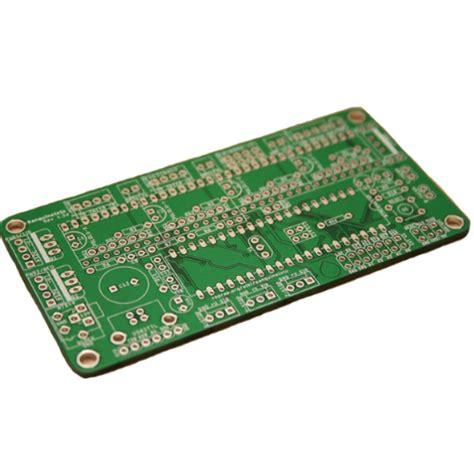

FR4 is a grade designation assigned by the National Electrical Manufacturers Association (NEMA) for glass-reinforced epoxy laminate materials. The “FR” stands for Flame Retardant, and the “4” indicates the woven glass reinforcement used in the material.

The composition of FR4 consists of two main components:

- Woven fiberglass cloth: This provides the structural strength and dimensional stability to the PCB.

- Epoxy resin: The epoxy resin is used as a binder to hold the fiberglass cloth together and provide insulation between the copper layers.

The combination of these materials results in a PCB substrate that offers excellent properties for electronic applications.

Properties of FR4 PCB Material

FR4 PCB material exhibits several desirable properties that make it suitable for a wide range of applications. These properties include:

- High mechanical strength and dimensional stability

- Excellent electrical insulation properties

- Good thermal stability and flame resistance

- Resistance to moisture absorption

- Suitable for high-frequency applications

The table below summarizes some of the key properties of FR4 PCB material:

| Property | Value |

|---|---|

| Dielectric Constant (1 MHz) | 4.3 – 4.9 |

| Dissipation Factor (1 MHz) | 0.02 |

| Dielectric Strength | 20 – 28 kV/mm |

| Thermal Conductivity | 0.3 – 0.4 W/m·K |

| Glass Transition Temperature | 130 – 140°C |

| Flexural Strength | 415 – 585 MPa |

| Moisture Absorption | 0.15 – 0.20% |

Advantages of Using FR4 PCB Material

FR4 PCB material offers several advantages over other PCB substrate materials, contributing to its widespread use in the electronics industry.

1. Cost-effectiveness

FR4 is a relatively inexpensive material compared to other high-performance PCB substrates. Its cost-effectiveness makes it an attractive choice for many applications, especially in large-scale production.

2. Versatility

FR4 PCB material is suitable for a wide range of applications, from simple single-layer boards to complex multi-layer PCBs. It can be used in various industries, including consumer electronics, automotive, aerospace, and medical devices.

3. Reliability

The excellent mechanical and thermal properties of FR4 make it a reliable choice for PCBs. Its high glass transition temperature and flame resistance ensure that the PCB can withstand harsh operating conditions without compromising its performance.

4. Ease of processing

FR4 PCB material is easy to process using standard PCB manufacturing techniques, such as drilling, routing, and plating. This ease of processing contributes to lower manufacturing costs and faster production times.

Applications of FR4 PCB

FR4 PCB material is used in a vast array of electronic applications across various industries. Some of the common applications include:

- Consumer electronics: Smartphones, laptops, tablets, and other portable devices

- Automotive electronics: Engine control units, infotainment systems, and sensors

- Industrial electronics: Control systems, power supplies, and automation equipment

- Medical devices: Diagnostic equipment, monitoring systems, and implantable devices

- Aerospace and defense: Avionics, communication systems, and military equipment

Limitations of FR4 PCB Material

Despite its many advantages, FR4 PCB material does have some limitations that should be considered when designing and manufacturing PCBs.

1. High-frequency performance

While FR4 is suitable for many high-frequency applications, its performance may be limited at very high frequencies (above 10 GHz) due to its relatively high dielectric constant and dissipation factor. For these applications, specialized PCB Materials like Rogers or PTFE may be more appropriate.

2. Thermal management

FR4 PCB material has a relatively low thermal conductivity, which can lead to heat build-up in high-power applications. In such cases, additional thermal management techniques, such as heat sinks or thermal vias, may be necessary to ensure proper heat dissipation.

3. Moisture absorption

Although FR4 has a low moisture absorption rate compared to other PCB materials, it can still absorb moisture over time, potentially leading to delamination or other reliability issues. Proper storage and handling of FR4 PCBs are essential to minimize moisture absorption.

Variations of FR4 PCB Material

There are several variations of FR4 PCB material available, each with slightly different properties tailored to specific applications.

1. High Tg FR4

High Tg (glass transition temperature) FR4 is a variant with improved thermal stability, typically featuring a Tg of 170°C or higher. This material is suitable for applications that require higher operating temperatures or increased reliability.

2. Halogen-free FR4

Halogen-free FR4 is a more environmentally friendly version of the standard FR4 material. It uses halogen-free flame retardants, which reduce the release of toxic substances during combustion. This variant is becoming increasingly popular due to growing environmental concerns and regulations.

3. Lead-free compatible FR4

Lead-free compatible FR4 is designed to withstand the higher temperatures required for lead-free soldering processes. This material has improved thermal stability and reduced moisture absorption to ensure reliable performance in lead-free manufacturing environments.

Frequently Asked Questions (FAQ)

-

What does FR4 stand for in PCB?

FR4 stands for Flame Retardant 4, which is a grade designation for glass-reinforced epoxy laminate materials used in PCBs. -

Is FR4 the best material for PCBs?

FR4 is one of the most widely used and versatile PCB materials, offering a good balance of cost, performance, and reliability. However, for some high-frequency or high-temperature applications, other specialized materials may be more suitable. -

What is the difference between FR2 and FR4 PCB?

FR2 is a lower-grade PCB material that uses a phenolic resin instead of epoxy. It has lower mechanical and thermal properties compared to FR4 and is typically used in low-cost, low-performance applications. -

Can FR4 PCBs be used for high-frequency applications?

Yes, FR4 PCBs can be used for many high-frequency applications up to around 10 GHz. However, for very high frequencies, specialized materials like Rogers or PTFE may offer better performance. -

How do I store FR4 PCBs to prevent moisture absorption?

FR4 PCBs should be stored in a cool, dry environment with a relative humidity of less than 50%. They should be kept in sealed moisture barrier bags with desiccants to absorb any excess moisture.

Conclusion

FR4 PCB material is the most widely used substrate for printed circuit boards due to its excellent combination of mechanical, electrical, and thermal properties. Its cost-effectiveness, versatility, and reliability make it a suitable choice for a wide range of electronic applications across various industries.

While FR4 does have some limitations, such as its performance at very high frequencies and its relatively low thermal conductivity, these can be addressed through proper design and the use of specialized variants or additional manufacturing techniques.

As the electronics industry continues to evolve, FR4 PCB material remains a crucial component in the manufacturing of reliable, high-performance printed circuit boards.

No responses yet