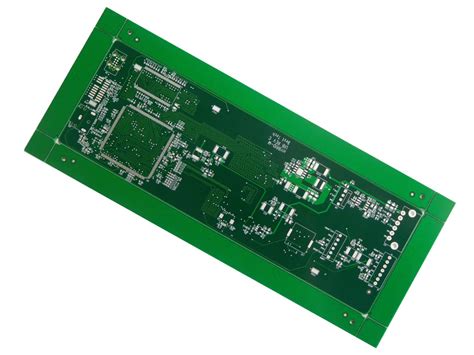

What is FR4?

FR4 is a type of laminate material that consists of multiple layers of woven fiberglass cloth impregnated with epoxy resin. The “FR” in FR4 stands for “Flame Retardant,” indicating its excellent Fire-Resistant properties. The number “4” represents the specific grade of flame retardancy.

FR4 has several advantages that make it an ideal choice for PCB manufacturing:

- High mechanical strength and durability

- Excellent electrical insulation properties

- Good thermal stability

- Flame retardancy

- Dimensional stability

The Manufacturing Process of FR4

The manufacturing process of FR4 laminated fiberglass involves several stages. Let’s take a closer look at each step:

Step 1: Preparing the Fiberglass Cloth

The first step in FR4 manufacturing is preparing the fiberglass cloth. The fiberglass cloth is made from fine glass fibers woven together in a specific pattern. The most common weave patterns used in FR4 are plain weave and twill weave.

| Weave Pattern | Description |

|---|---|

| Plain Weave | Simple crisscross pattern, provides good stability |

| Twill Weave | Diagonal pattern, offers higher mechanical strength |

The fiberglass cloth is carefully inspected for any defects or impurities before proceeding to the next step.

Step 2: Impregnating the Fiberglass Cloth with Epoxy Resin

Once the fiberglass cloth is ready, it is impregnated with epoxy resin. The epoxy resin is a thermoset polymer that provides excellent adhesion, mechanical strength, and electrical insulation properties.

The impregnation process involves dipping the fiberglass cloth into a bath of liquid epoxy resin. The cloth is then passed through a series of rollers to ensure even distribution of the resin and remove any excess material.

Step 3: Drying and Partially Curing the Impregnated Cloth

After impregnation, the cloth undergoes a drying and partial curing process. The impregnated cloth is passed through a heated chamber to remove any remaining solvents and partially cure the epoxy resin.

The partial curing process, also known as B-staging, allows the material to retain its flexibility for further processing while providing some degree of stability.

Step 4: Cutting and Layering the Impregnated Cloth

The partially cured impregnated cloth is then cut into the desired sizes and shapes. These cut pieces are carefully stacked and layered to achieve the required thickness of the FR4 laminate.

The number of layers and their orientation depend on the specific requirements of the end application. The layering process is critical to ensure uniform thickness and prevent any air gaps or voids between the layers.

Step 5: Lamination under Heat and Pressure

The stacked layers of impregnated cloth are then placed in a lamination press. The lamination process involves applying heat and pressure to the layered stack.

The typical lamination conditions for FR4 are:

| Parameter | Value |

|---|---|

| Temperature | 165°C – 185°C |

| Pressure | 200 – 400 psi |

| Duration | 1 – 2 hours |

Under these conditions, the epoxy resin fully cures and bonds the fiberglass layers together, forming a solid, homogeneous FR4 laminate.

Step 6: Cooling and Finalizing the FR4 Laminate

After lamination, the FR4 laminate is allowed to cool down gradually to room temperature. The slow cooling process helps prevent any warping or dimensional instability.

Once cooled, the FR4 laminate undergoes a final inspection to ensure its quality and conformity to the specified requirements. The laminate is then trimmed to the desired dimensions and packaged for further processing or shipping.

Properties and Applications of FR4

FR4 laminated fiberglass exhibits several key properties that make it suitable for various applications. Let’s explore some of its important characteristics and common uses.

Electrical Properties

FR4 has excellent electrical insulation properties, making it ideal for PCB manufacturing. Some of its electrical properties include:

- High dielectric strength

- Low Dielectric Constant

- Low dissipation factor

These properties ensure reliable electrical performance and minimize signal loss in electronic circuits.

Mechanical Properties

FR4 possesses good mechanical strength and stability. It offers:

- High tensile strength

- High flexural strength

- Good impact resistance

- Dimensional stability

These mechanical properties enable FR4 to withstand the stresses and strains encountered during PCB manufacturing and operation.

Thermal Properties

FR4 exhibits good thermal stability and flame retardancy. It has:

- Glass transition temperature (Tg) around 130°C – 140°C

- Thermal expansion coefficient (CTE) close to that of copper

- UL 94 V-0 flame retardancy rating

The thermal properties of FR4 ensure reliable performance in high-temperature environments and provide fire safety in electronic applications.

Applications

FR4 laminated fiberglass finds widespread use in various industries. Some of its common applications include:

- Printed Circuit Boards (PCBs)

- Automotive electronics

- Telecommunications equipment

- Aerospace and defense systems

- Industrial control panels

- Consumer electronics

The versatility and reliability of FR4 make it a preferred choice for a wide range of electronic applications.

Frequently Asked Questions (FAQ)

-

What is the difference between FR4 and other PCB materials?

FR4 is a specific grade of laminated fiberglass material that offers excellent electrical insulation, mechanical strength, and flame retardancy. Other PCB Materials, such as polyimide or PTFE, may have different properties and are used for specific applications that require higher temperature resistance or lower dielectric constant. -

Can FR4 be used for high-frequency applications?

While FR4 is suitable for many general-purpose electronic applications, it may not be the best choice for high-frequency applications. At higher frequencies, FR4’s dielectric constant and dissipation factor can lead to signal integrity issues. For high-frequency applications, materials with lower dielectric constant and dissipation factor, such as Rogers’ laminates, are often preferred. -

What is the typical thickness of FR4 laminates?

FR4 laminates are available in various thicknesses, typically ranging from 0.2mm to 3.2mm. The thickness is determined by the number of fiberglass layers and the specific requirements of the application. Common thicknesses for PCBs are 0.8mm, 1.6mm, and 2.4mm. -

How does the weave pattern of the fiberglass cloth affect the properties of FR4?

The weave pattern of the fiberglass cloth influences the mechanical and electrical properties of FR4. Plain weave offers good stability and is commonly used for general-purpose applications. Twill weave provides higher mechanical strength and is often used in high-reliability applications. The choice of weave pattern depends on the specific requirements of the end application. -

Can FR4 be recycled?

Recycling FR4 laminates is challenging due to the composite nature of the material. The fiberglass and epoxy resin are difficult to separate, making recycling processes complex. However, efforts are being made to develop recycling technologies for FR4 and other composite materials to reduce environmental impact and promote sustainability in the electronics industry.

Conclusion

FR4 laminated fiberglass is a crucial material in the electronics industry, widely used for manufacturing printed circuit boards. Its manufacturing process involves preparing the fiberglass cloth, impregnating it with epoxy resin, and laminating under heat and pressure to form a solid, homogeneous material.

FR4’s excellent electrical insulation, mechanical strength, and flame retardancy make it suitable for a wide range of electronic applications. Understanding the manufacturing process and properties of FR4 is essential for designers, engineers, and manufacturers in the electronics industry to ensure reliable and high-quality products.

As technology advances and the demand for high-performance electronics grows, the development of new materials and manufacturing techniques will continue to shape the future of the electronics industry. FR4 laminated fiberglass remains a fundamental material that provides a solid foundation for building reliable and robust electronic devices.

No responses yet