Factors Affecting PCB Frequency Range

Several factors contribute to the frequency range of a PCB. These factors include:

1. Material Properties

The choice of substrate material significantly impacts the frequency range of a PCB. The two most important material properties to consider are:

-

dielectric constant (Dk): The dielectric constant measures the substrate’s ability to store electrical energy. Materials with lower Dk values are more suitable for high-frequency applications, as they minimize signal delay and reduce power loss.

-

Dissipation Factor (Df): The dissipation factor quantifies the substrate’s power loss due to dielectric heating. Lower Df values are desirable for High-frequency PCBs, as they minimize signal attenuation and power dissipation.

Common PCB substrate materials and their properties:

| Material | Dielectric Constant (Dk) | Dissipation Factor (Df) |

|---|---|---|

| FR-4 | 4.2 – 4.5 | 0.02 – 0.03 |

| Rogers ro4350B | 3.48 | 0.0037 |

| PTFE | 2.1 | 0.0002 |

| Polyimide | 3.5 | 0.002 |

2. Trace Geometry and Impedance Matching

The geometry of the PCB traces, including their width, thickness, and spacing, plays a crucial role in determining the frequency range. At high frequencies, the traces behave as transmission lines, and their impedance must be matched to minimize signal reflections and distortions.

The characteristic impedance of a trace is given by:

Z₀ = (87 / √ε_r) * ln(5.98 * h / (0.8 * w + t))

Where:

– Z₀ is the characteristic impedance (in ohms)

– ε_r is the dielectric constant of the substrate

– h is the substrate thickness (in mils)

– w is the trace width (in mils)

– t is the trace thickness (in mils)

To maintain signal integrity, it is essential to design traces with consistent impedance and minimize discontinuities, such as vias and sharp bends.

3. Layering and Grounding

The number of layers in a PCB and the proper use of ground planes significantly affect its frequency range. Multi-layer PCBs with dedicated ground planes offer better high-frequency performance compared to single-layer boards. Ground planes provide a low-impedance return path for high-frequency signals, reducing electromagnetic interference (EMI) and improving signal integrity.

Proper grounding techniques, such as the use of ground vias and stitching capacitors, help minimize ground bounce and reduce high-frequency noise.

Typical Frequency Ranges for Different PCB Types

The frequency range of a PCB depends on its intended application and the design considerations mentioned above. Here are some common PCB types and their typical frequency ranges:

1. Single-Layer PCBs

Single-layer PCBs are the simplest and most cost-effective type of PCB. They are suitable for low-frequency applications up to a few hundred kilohertz (kHz). Single-layer PCBs are commonly used in simple devices, such as power supplies, LED lighting, and basic control circuits.

2. Double-Layer PCBs

Double-layer PCBs offer improved performance compared to single-layer boards, with a typical frequency range of up to a few megahertz (MHz). They are widely used in consumer electronics, such as smartphones, laptops, and televisions. Double-layer PCBs provide better signal routing options and can incorporate basic ground planes for improved signal integrity.

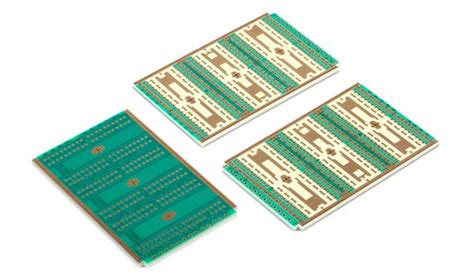

3. Multi-Layer PCBs

Multi-layer PCBs, with four or more layers, are designed for high-frequency applications ranging from tens of megahertz to several gigahertz (GHz). They are used in advanced electronic systems, such as high-speed digital circuits, RF and microwave devices, and aerospace and defense applications.

Multi-layer PCBs offer several advantages for high-frequency operation:

- Dedicated ground and power planes for low-impedance current return paths

- Controlled impedance traces for optimized signal transmission

- Reduced crosstalk and EMI through proper layer arrangement and shielding

Here is a table summarizing the typical frequency ranges for different PCB types:

| PCB Type | Typical Frequency Range |

|---|---|

| Single-Layer | Up to a few hundred kHz |

| Double-Layer | Up to a few MHz |

| Multi-Layer (4+) | Tens of MHz to several GHz |

High-Frequency PCB Design Considerations

To ensure optimal performance in high-frequency PCB designs, consider the following guidelines:

- Choose low-loss substrate materials with low dielectric constant and dissipation factor values.

- Use controlled impedance traces and maintain consistent trace geometry to minimize signal reflections and distortions.

- Implement proper grounding techniques, such as ground planes, ground vias, and stitching capacitors, to reduce ground bounce and high-frequency noise.

- Minimize the use of vias, especially in high-speed signal paths, and use via shielding or back-drilling techniques when necessary.

- Follow recommended layout practices, such as avoiding sharp bends, minimizing trace lengths, and providing adequate spacing between traces to reduce crosstalk.

- Use appropriate signal integrity analysis tools, such as time-domain reflectometry (TDR) and vector network analyzers (VNA), to characterize and optimize the high-frequency performance of the PCB.

Frequently Asked Questions (FAQ)

1. What is the maximum frequency a PCB can handle?

The maximum frequency a PCB can handle depends on various factors, such as the substrate material, trace geometry, and layering. Multi-layer PCBs with low-loss substrates and controlled impedance traces can operate at frequencies up to several gigahertz (GHz). However, the actual maximum frequency will depend on the specific design and application requirements.

2. Can FR-4 PCBs be used for high-frequency applications?

FR-4 is a popular and cost-effective substrate material for PCBs. While it is suitable for many general-purpose applications, its relatively high dielectric constant and dissipation factor limit its performance at high frequencies. For high-frequency applications above a few gigahertz, it is recommended to use low-loss substrate materials, such as Rogers RO4350B or PTFE.

3. What is the impact of PCB thickness on high-frequency performance?

PCB thickness can affect high-frequency performance in several ways. Thinner PCBs generally have lower inductance and can provide better high-frequency performance. However, thinner boards may also be more susceptible to mechanical stress and warping. The choice of PCB thickness should balance electrical performance, mechanical stability, and manufacturing considerations.

4. How can I reduce crosstalk in high-frequency PCBs?

To reduce crosstalk in high-frequency PCBs, consider the following techniques:

- Increase the spacing between adjacent traces, especially for high-speed signals.

- Use guard traces or ground planes between sensitive signal traces to provide shielding.

- Route high-speed signals on inner layers, sandwiched between ground planes, to minimize coupling with other signals.

- Minimize parallel run lengths of high-speed traces to reduce the coupling area.

- Use differential signaling techniques, such as LVDS or CML, to cancel out electromagnetic fields and reduce crosstalk.

5. What is the role of via stitching in high-frequency PCBs?

Via stitching is a technique used in high-frequency PCBs to provide a low-impedance connection between ground planes on different layers. By placing multiple vias around the perimeter of the board or near critical components, via stitching helps minimize ground bounce and reduces high-frequency noise. This technique is particularly important for multi-layer PCBs operating at high frequencies, as it ensures a stable and consistent ground reference throughout the board.

Conclusion

Understanding the frequency range of a PCB is crucial for designing reliable and high-performance electronic systems. The frequency range of a PCB depends on various factors, including the substrate material, trace geometry, impedance matching, layering, and grounding techniques. By carefully considering these factors and following best design practices, engineers can create PCBs that operate effectively across a wide range of frequencies, from a few kilohertz to several gigahertz.

As the demand for high-speed and high-frequency electronic devices continues to grow, it is essential for PCB designers to stay updated with the latest materials, technologies, and design methodologies. By doing so, they can overcome the challenges associated with high-frequency PCB design and develop innovative solutions that push the boundaries of electronic performance.

No responses yet