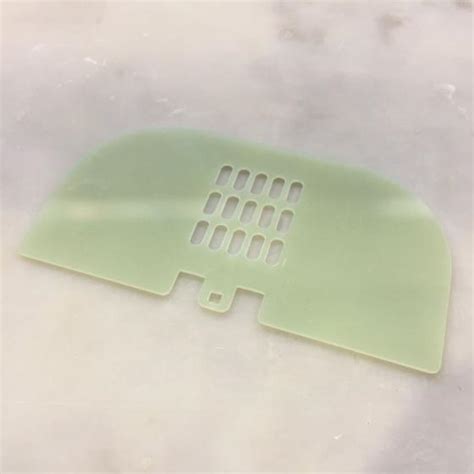

What is FR4?

FR4 is a composite material composed of woven fiberglass cloth with an epoxy resin binder. The “FR” stands for “Flame Retardant,” indicating that the material has been treated to resist the spread of flames in case of a fire. The “4” refers to the specific grade of the material, which is determined by the glass transition temperature (Tg) and the flammability rating.

Composition of FR4

FR4 is made by impregnating a woven fiberglass cloth with an epoxy resin and then curing it under heat and pressure. The fiberglass cloth provides the mechanical strength and dimensional stability, while the epoxy resin acts as a binder and provides the electrical insulation properties.

The fiberglass used in FR4 is typically E-glass, which is a low-alkali borosilicate glass with good electrical and mechanical properties. The glass fibers are woven into a fabric with a plain or twill weave pattern, depending on the desired properties of the final product.

The epoxy resin used in FR4 is a thermosetting polymer that crosslinks and hardens when exposed to heat. It is formulated with flame retardants, such as bromine or phosphorus compounds, to improve the fire resistance of the material.

Properties of FR4

FR4 has several desirable properties that make it suitable for use in electronic applications:

- Mechanical strength: The fiberglass reinforcement provides high tensile and flexural strength, making FR4 resistant to bending and breaking.

- Dimensional stability: FR4 has a low coefficient of thermal expansion (CTE), which means it maintains its dimensions over a wide temperature range. This is important for maintaining the integrity of the copper traces on a PCB.

- Electrical insulation: The epoxy resin provides excellent electrical insulation, with a Dielectric constant of around 4.5 and a Dielectric Strength of 20-28 kV/mm.

- Thermal stability: FR4 has a glass transition temperature (Tg) of around 130-140°C, which means it can withstand the high temperatures encountered during soldering and other assembly processes.

- Flame retardancy: The flame retardants in the epoxy resin help to prevent the spread of flames in case of a fire, making FR4 suitable for use in safety-critical applications.

Here is a table summarizing the key properties of FR4:

| Property | Value |

|---|---|

| Tensile strength | 310-380 MPa |

| Flexural strength | 415-585 MPa |

| CTE | 12-16 ppm/°C |

| Dielectric constant | 4.2-4.9 |

| Dielectric strength | 20-28 kV/mm |

| Tg | 130-140°C |

Is FR4 a Fiberglass?

Strictly speaking, FR4 is not a fiberglass, but rather a composite material that contains fiberglass as one of its components. Fiberglass refers specifically to the reinforcing glass fibers, while FR4 is the complete composite material that includes both the fiberglass and the epoxy resin matrix.

However, in common usage, the term “fiberglass” is often used to refer to the complete composite material, including both the glass fibers and the resin matrix. In this sense, it is not incorrect to say that FR4 is a type of fiberglass, although it is more accurate to describe it as a fiberglass-reinforced epoxy composite.

Other Types of Fiberglass Composites

FR4 is just one example of a fiberglass-reinforced composite material. Other common types include:

- G10: A high-pressure thermoset plastic laminate with a fiberglass reinforcement. It has similar properties to FR4 but without the flame retardant additives.

- G11: A high-temperature version of G10 with a higher glass transition temperature (Tg) of around 170°C.

- FR5: A fiberglass-reinforced epoxy composite with a higher Tg and better thermal stability than FR4.

- CEM-1: A composite material made with a fiberglass-reinforced epoxy surface bonded to a non-woven cellulose paper core. It is lower cost than FR4 but with reduced properties.

Here is a table comparing the properties of some common fiberglass composites:

| Material | Tg (°C) | Dielectric Constant | Dielectric Strength (kV/mm) |

|---|---|---|---|

| FR4 | 130-140 | 4.2-4.9 | 20-28 |

| G10 | 130 | 4.8-5.0 | 20 |

| G11 | 170 | 4.8 | 20 |

| FR5 | 170-180 | 4.3-4.7 | 25-30 |

| CEM-1 | 125 | 4.5-5.0 | 15-20 |

Applications of FR4

FR4 is widely used in the electronics industry for the fabrication of printed circuit boards (PCBs). PCBs are the backbone of modern electronic devices, providing the interconnections between components such as integrated circuits, capacitors, and resistors.

FR4 in PCBs

FR4 is the most common substrate material for PCBs due to its excellent balance of mechanical, electrical, and thermal properties. The copper traces that form the electrical connections on the PCB are etched onto the FR4 substrate using a photolithographic process.

The fiberglass reinforcement in FR4 provides the necessary mechanical strength to support the copper traces and prevent the board from warping or cracking during the assembly process. The epoxy resin provides the electrical insulation between the copper layers and helps to dissipate heat generated by the electronic components.

FR4 PCBs are used in a wide range of electronic applications, from consumer devices like smartphones and laptops to industrial control systems and aerospace equipment. They are available in a variety of thicknesses and copper weights to suit different design requirements.

Other Applications of FR4

In addition to PCBs, FR4 is also used in other applications where its unique combination of properties is advantageous:

- Structural components: FR4 can be used to make lightweight, high-strength structural components for aerospace, automotive, and marine applications.

- Electrical insulation: FR4 sheets and rods are used as electrical insulators in transformers, switchgear, and other high-voltage equipment.

- Thermal management: FR4 can be used as a substrate for high-power LEDs and other heat-generating components, helping to dissipate heat and prevent thermal damage.

Frequently Asked Questions (FAQ)

-

What does FR4 stand for?

FR4 stands for “Flame Retardant 4,” indicating that the material has been treated with flame retardants and meets the UL94 V-0 flammability rating. -

What is the difference between FR4 and G10?

FR4 and G10 are similar composite materials made with fiberglass and epoxy resin. The main difference is that FR4 contains flame retardant additives, while G10 does not. FR4 is more commonly used in PCBs due to its better fire resistance. -

Can FR4 be used for high-temperature applications?

Standard FR4 has a glass transition temperature (Tg) of around 130-140°C, which limits its use in high-temperature applications. For higher temperatures, materials like FR5 or polyimide can be used instead. -

Is FR4 waterproof?

FR4 is not inherently waterproof, but it has good moisture resistance. For applications that require full waterproofing, the FR4 can be coated or encapsulated with a waterproof material such as conformal coating or potting compound. -

How is FR4 manufactured?

FR4 is manufactured by impregnating a woven fiberglass cloth with an epoxy resin containing flame retardant additives. The impregnated cloth is then dried, cut to size, and laminated under heat and pressure to form the final composite material. Copper foil can be bonded to one or both sides of the FR4 laminate to create a PCB substrate.

Conclusion

In conclusion, FR4 is a composite material that contains fiberglass as a reinforcing component, along with an epoxy resin matrix. While it is not strictly accurate to call FR4 a fiberglass, the term is often used in industry to refer to the complete composite material.

FR4 is an essential material in the electronics industry, particularly for the fabrication of PCBs. Its unique combination of mechanical strength, electrical insulation, thermal stability, and flame retardancy make it an ideal substrate for a wide range of electronic applications.

As electronic devices continue to become more complex and demanding, the development of new materials and manufacturing processes for PCBs will be an ongoing area of research and innovation. FR4 and other fiberglass-reinforced composites will likely continue to play a critical role in this field for the foreseeable future.

No responses yet